VR4 Elektra-S

VR4 Elektra “S” is a special version of the model from which it derives, specifically designed to pack products without tray or support, arranged in one or two rows.

In particular, it is equipped with a special conveyor, fitted with a system of flexible mats that allow it to control and protect the product from the moment it is placed until it reaches the sealing area.

From here, a system of soft brushes picks up the product and keeps it stable while it is being packaged.

Thanks to these features VR 4 Elektra S makes it possible to create trayless packs, guaranteeing a mono-material solution (only the packaging film) and significant savings in packaging material and costs.

It works well with a variety of packaging materials, including recyclables, biodegradable, compostable and paper films that the market demands with a view to environmental sustainability.

For these reasons, the VR 4 Elektra S stands as an ideal solution to the need to reduce the environmental impact of packaging while ensuring product preservation and presentation.

features

- Infeed conveyor with mats and flaps, Feed conveyor with mats and flaps, special conveyor to protect and place the product stably despite theabsenceofsupport.

- Accompanying brushes system , to accompany the product and ensure its stability during the packaging phase.

- Extra long infeed conveyor, providing additional space for operators to correctly position the product on the machine conveyor.

- Removableproductpusherfor quick changeovers.

- Storable bag lengthandpusher head-cutterphasefor quick and easy format changeovers.

- Stop in phase, avoids overheating of the film in case of prolonged stop, preserving the seals.

- Immediate jaw retraction in case of jamming, facilitates product evacuation and preserves the head-cutter mechanics.

- Jaw release with push button, for precise and efficient resetting in the event of entrapment.

- Universal forming tunnel, to adapt to any format, allowing the width and height of the bag to be adjusted on demand.

- Self-centring reel holder, regardless of the reel width used, the film is always centred without the need for any adjustment.

- Progressive reel brake, as the film reel is consumed, the brake is automatically changed so that the operator does not have to worry about it.

- Control panel with colour touch screen, allowing quick format changeover and intuitive management of all the machine parameterisation options.

- Three pairs sealing wheelsguarantee a better result in longitudinal bag sealing.

- Instantaneous speed reducer, to facilitate machine operation in situations that require lower packaging speed and optimise times.

- Preventive maintenance warnings, to warn of the appropriate moment for an overhaul.

options

VR4 Elektra S can be customised with multiple accessories to increase efficiency based on customer needs and/or product requirements.

Some of the accessories are:

- Stop no Film , stops the machine automatically if the film reel runs out.

- Photo-eye system for registered film, allowing the use of films printed with marks to centre the design on the product.

- Second reel holder, to have a reel of the same size or of another format readily available, speeding up replacement.

- Printers/Markers, to print information such as batch number, production/expiration date or barcodes and images directly onto the film in real time.

- Labellers, to apply and print labels on the finished pack or directly on the film before forming.

- Accumulation rotary table, placed at the exit of the flow-wrapper, receives the already packaged products to facilitate successive packaging operations.

- Inverse version, with product loading from left to right to adapt to the available space or to integrated production lines.

- Stop no product, temporarily stops the machine when product has not been loaded on the in-feed conveyor

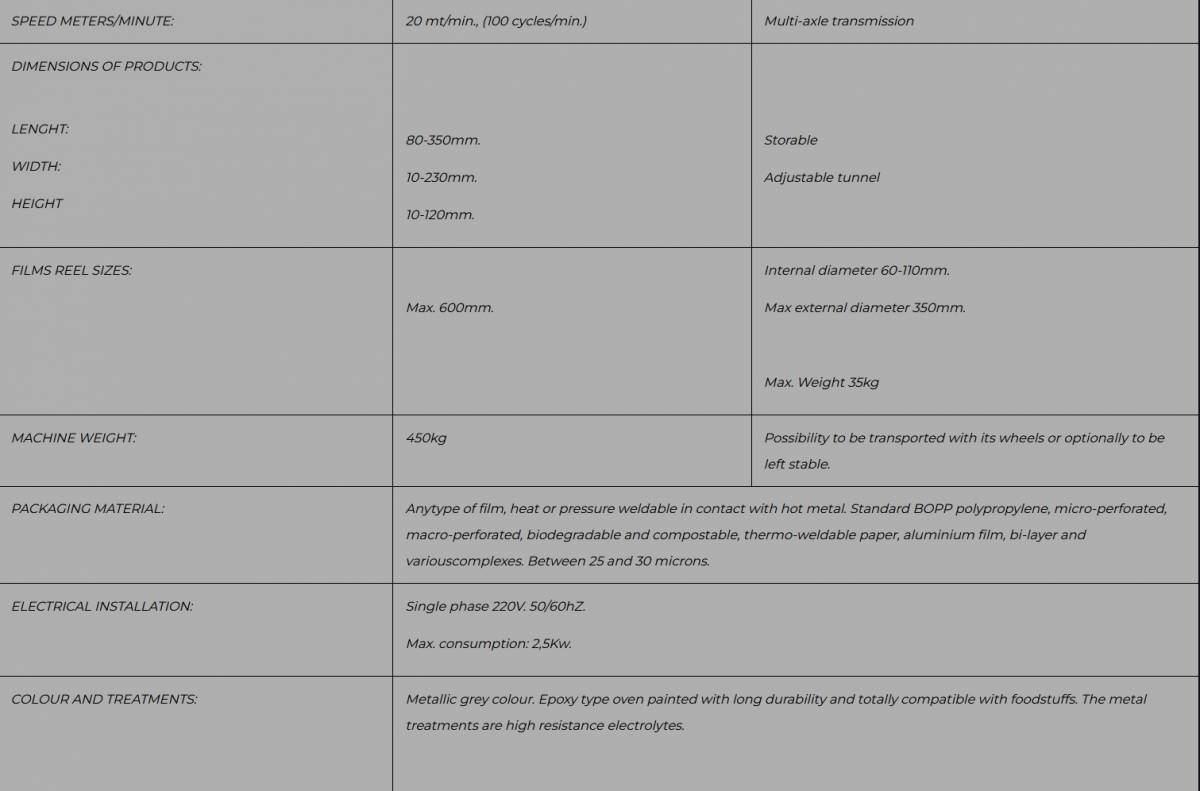

| SPEED METERS/MINUTE: | 20 mt/min., (100 cycles/min.) | Multi-axle transmission |

| DIMENSIONS OF PRODUCTS:

WIDTH: HEIGHT |

80-350mm. 10-230mm. 10-120mm. |

Storable Adjustable tunnel |

| FILMS REEL SIZES: |

Max. 600mm.

|

Internal diameter 60-110mm.

Max external diameter 350mm.

Max. Weight 35kg |

| MACHINE WEIGHT: | 450kg | Possibility to be transported with its wheels or optionally to be left stable. |

| PACKAGING MATERIAL: | Anytype of film, heat or pressure weldable in contact with hot metal. Standard BOPP polypropylene, micro-perforated, macro-perforated, biodegradable and compostable, thermo-weldable paper, aluminium film, bi-layer and variouscomplexes. Between 25 and 30 microns. | |

| ELECTRICAL INSTALLATION: | Single phase 220V. 50/60hZ.

Max. consumption: 2,5Kw. |

|

| COLOUR AND TREATMENTS: | Metallic grey colour. Epoxy type oven painted with long durability and totally compatible with foodstuffs. The metal treatments are high resistance electrolytes.

|

|