T80 ADVANCE

T80 Advance represents an excellent combination of performance and ease of use. It is particularly suitable for medium-high production, depending on the size of the trays and the type of packaging material used.

With its compact size, the machine can easily fit in limited spaces and integrate easily with peripherals to complete a product’s packaging process (such as dosing, labeling, and weight-checking systems). The machine can efficiently work with different product formats, making it a suitable solution for those managing a varied production. The possibility of being used with different types of packaging materials with and without modified atmosphere packaging (MAP), skin, vacuum, and lids, helps to make it an exceptionally versatile solution able to meet the needs of those looking for packaging solutions with materials that the market demands for environmental sustainability.

Our wide-reel system allows for increased productivity, reducing downtime for film replacement and saving space for reel stock.

The T80 Advance can tackle demanding jobs with ease.

As a result, it is simple to operate, easy to learn, and does not require operators with in-depth technical knowledge.

Innovative diagnostic software, with specific alerts for each area of the machine, ensures high autonomy of operation and helps minimize downtime on the packaging line. The high-quality materials used in constructing the T80 Advance can guarantee a long service life, minimizing and simplifying maintenance.

The construction quality and the mechanical assemblies’ performance enable it to cope with the wear and corrosion (generated by moisture, fluids, and dirt) associated with product packaging without any problems.

The machine includes components from the most technologically advanced

companies on the market.

features

- Servo-driven displacer for precise and fast product positioning.Mould transmission by servo motor

- Product transport, The product is moved by means of automatic belts synchronised with a single-step, 90-degree slider/positioner. This makes the machine totally autonomous.

- Speed can be memorised in each recipe, to facilitate format changeover.

- Positioning control by screen, possibility to parameterise stop and acceleration ramps.

- Temperature and sealing time control, independent temperature modules (for each cavity), memorisable in independent recipes.

- Control of independent drives, allowing productivity to be optimised according to the product to be heat-sealed.

- Misplaced product device, in case the product does not arrive in phase with the mold, it cancels its activation to avoid damage to the product.

- Immediate mould change without the need for tools.

- Film die-cutting by means of stainless steel blades, customised for each container.

- Stainless steel frame and covers, for less maintenance even with highly corrosive products.

- Insulated electrical panel, located in the upper part of the machine, away from possible splashes.

- Motorised film feed, with constant tension control for perfect sealing.

- Motorised film waste collector to optimise film consumption.

- Wide film reels, allowing greater working autonomy, extending the cycles between reel changes.

- Automatic product loader, automatically synchronises feeding with the machine carriage.

- Control panel with colour touch screen, allows quick format changeover and intuitive management of all the machine parameterisation options.

- Real-time diagnostics, displaying the machine’s operating status on the screen, to quickly locate possible anomalies.

- Preventive maintenance alerts, to signal the appropriate time for an overhaul.

options

TheT80Advancecan be customised with a variety of accessories to increase efficiency based on customer needs and/or product requirements.

Some of the accessories are:

- Automatic centering system for registered film, allows the use of printed films with speckles to centre the design on the product.

- Tray destacker, automatically dispenses empty trays from its own storage buffer.

- Automatic dispensers, automatically dispense the selected doses into each container/tray.

- Printers/Markers, to print information such as batch number, production/expiration date or barcodes and images directly onto the film in real time.

- Labellers, to print and apply labels on the finished pack or directly on the film before forming. Rotary table, positioned at the exit of the machine, receives the products already packaged to facilitate successive packaging operations.

- Metal detector, with and without rejection in case of contamination.

- Weight control, checks the weight of each tray and can be complemented with rejects or deviations for re-adjustment before thermosealing.

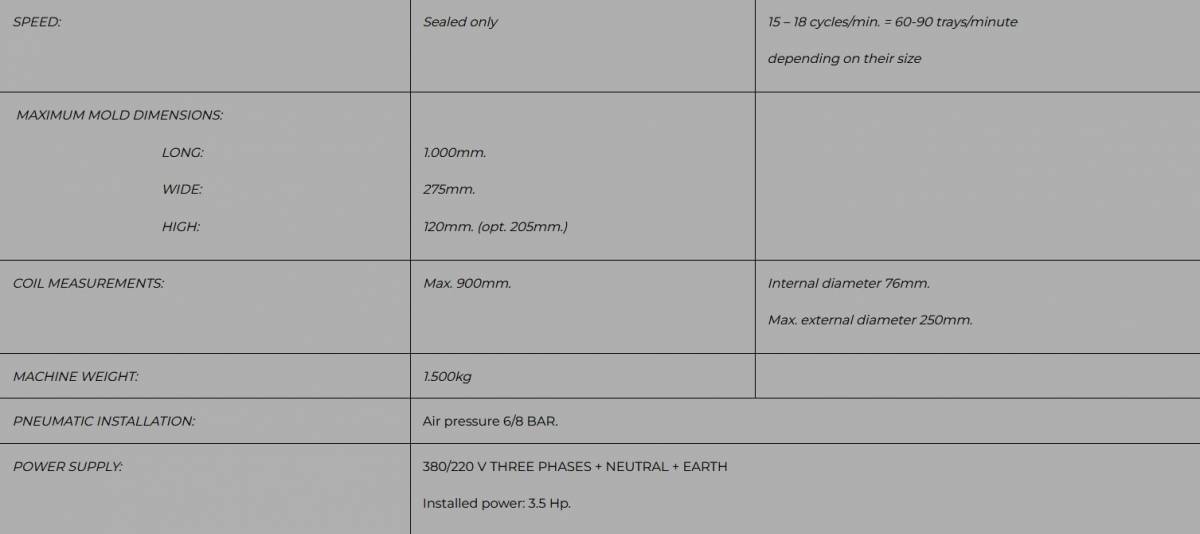

| SPEED: | Sealed only | 15 – 18 cycles/min. = 60-90 trays/minute

depending on their size |

| MAXIMUM MOLD DIMENSIONS:

LONG: WIDE: HIGH: |

1.000mm. 275mm. 120mm. (opt. 205mm.) |

|

| COIL MEASUREMENTS: | Max. 900mm.

|

Internal diameter 76mm.

Max. external diameter 250mm. |

| MACHINE WEIGHT: | 1.500kg | |

| PNEUMATIC INSTALLATION: | Air pressure 6/8 BAR. | |

| POWER SUPPLY: | 380/220 V THREE PHASES + NEUTRAL + EARTH

Installed power: 3.5 Hp. |

|