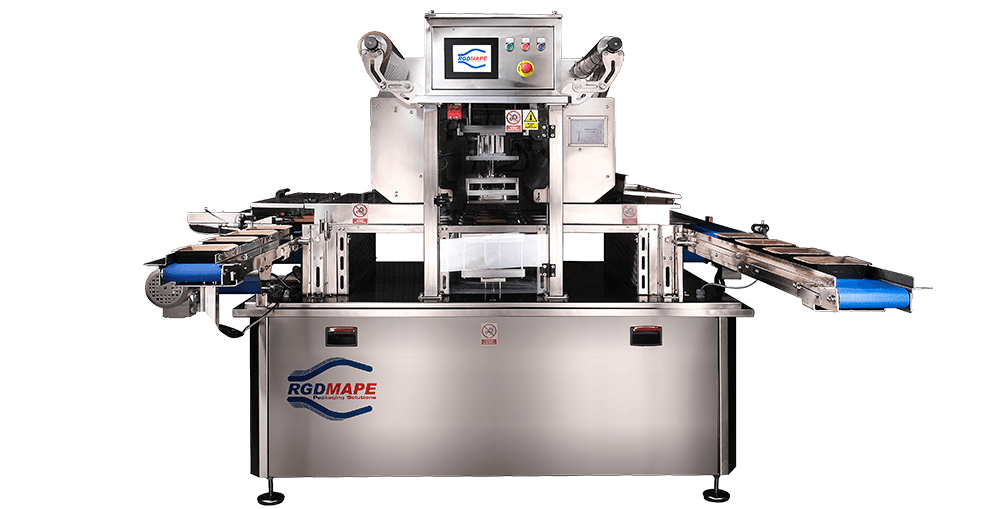

T60 Practika is the ideal solution for simple and fully automatic tray packaging.

As a result of many years of experience in tray packing, it represents an excellent combination of simplicity and performance.

The machine can easily adapt to most space requirements. And can quickly integrate with peripheral equipment used to complete the packaging process of a product (such as dosing, labeling, check weighing, and similar systems).

It can work with different product formats, making it a suitable solution for those managing a varied production. The possibility of using varying packaging materials with and without modified atmosphere (MAP), skin, vacuum, and lids makes it a remarkably versatile solution.

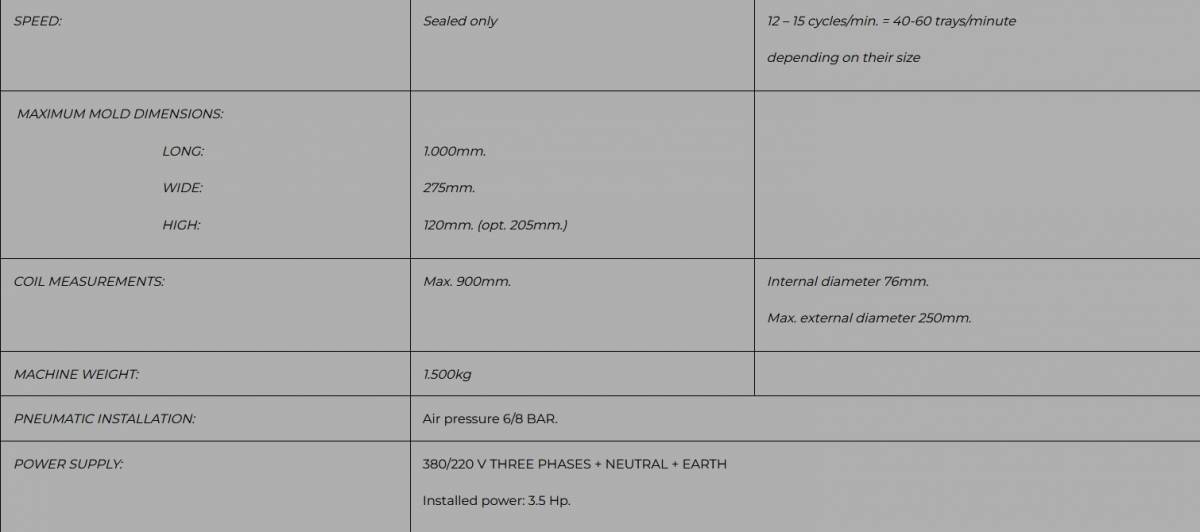

Our system of using wide reels increases productivity, reducing downtime for film replacement and saving space for reel stock.

The T60 Practika can handle demanding jobs with ease.

The operation is simple and easy to learn and does not require operators with in-depth technical knowledge.

The innovative diagnostic software, with specific warnings for each area of the machine, guarantees a high level of autonomy and helps to minimize downtime on the packaging line.

The high-quality materials used in constructing the T60 Practika guarantee a long service life, minimizing and simplifying maintenance.

The construction quality and the mechanical assemblies’ performance enable the machine to withstand the wear and corrosion (generated by moisture, fluids, and dirt) associated with product packaging without any problems.

The machine includes components from the most technologically advanced

companies on the market.