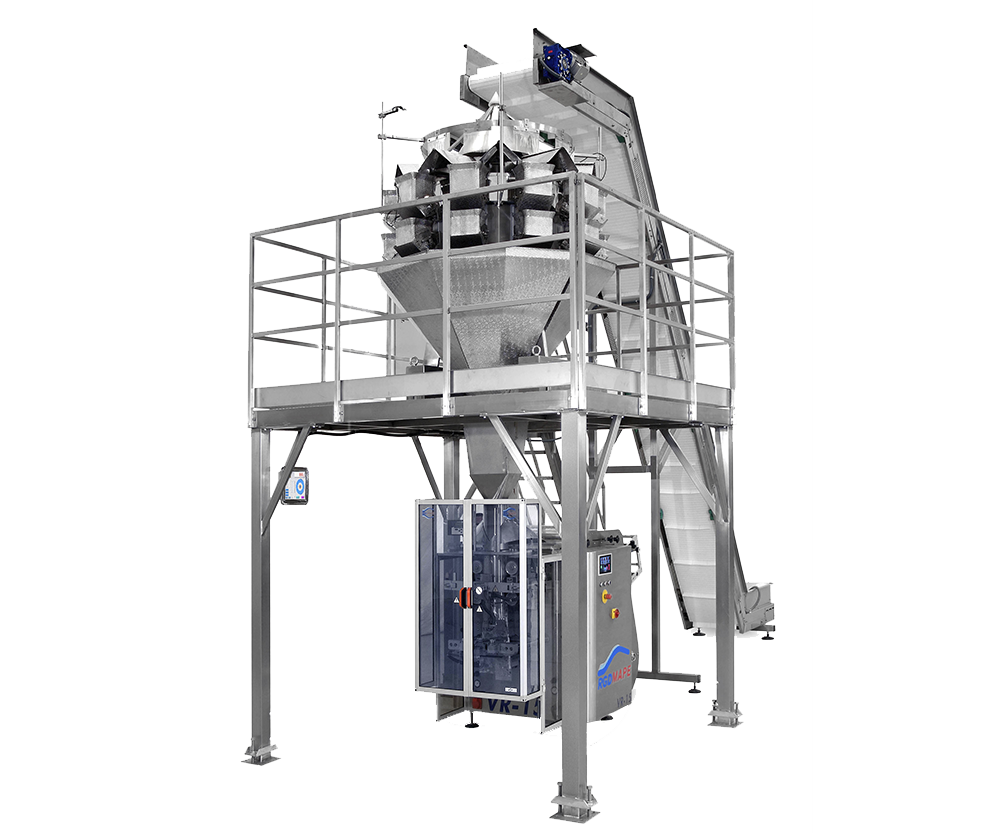

VR15

VR15 is an efficient, adaptable, and practical solution in the range of vertical packaging solutions, i.e., with infeed, bag forming, and sealing from top to bottom. This type of solution is particularly suitable for packaging bulk products, even in large quantities, which are difficult to handle with other packaging machines without proper support (trays, punnets, or other containers).

Simple in its use, the machine can thus be equipped to pack a wide range of products in the most diverse sectors. The VR15, as with RGDMAPE’s construction philosophy in general, offers the possibility of a customizable solution capable of adapting to different needs.

This flexibility is also evident in the possibility of building complete packaging lines of even very different sizes, performances, and characteristics around the machine.

Integration goes from the possible combination with an individual weighing and dosing system to high-performance multi-head weighing systems. In addition, the machine can be easily combined with the other peripherals that complete the vertical packaging lines.

No less important is the possibility of having the VR15 in an inclined version (VR15 I), an ideal solution for fragile products that require the smoothest possible descent and entry into the pack.

The machine makes it easy to work with different product formats, thus presenting itself as a suitable solution for those who need to handle various production. The ability to use it with different types of packaging materials helps make it a remarkably versatile solution that can meet the needs of those seeking packaging solutions with materials that the market requires for environmental sustainability. The high-quality materials used in the construction of the VR15 ensure its long service life, minimizing and simplifying maintenance.

The construction quality and the mechanical assemblies’ performance allow it to cope with the wear and corrosion (generated by moisture, fluids, and dirt) resulting from product packaging without any problems. The machine is manufactured with components from the most technologically advanced companies.

features

- Servo-driven jaws, for a precise and independent movement of the head.

- Solid structure, built in stainless steel.

- Motorised film unwinding for better film tension control.

- Film centring, byhandwheel moving the reel holder unit, for immediate reel centring.

- Expandable coil anchor, grips the coil with pneumatically activated slats, ensuring fast and effective gripping.

- Complete and compact forming tube for quick replacement.

- Vertical welder, with axial regulation. Possibility of second operation in the same cycle.

- Touch panel control, with intuitive screen design. Possibility of memorising up to 40 recipes.

- Hermetic electrical cabinet, with the possibility of choosing the side of the machine to be installed.

- Memorable temperatures for each recipe, to facilitate and make format changeover even faster.

- Preventive maintenance warnings, to warn of the appropriate time for a check-up

options

The VR15 can be customised with multiple accessories to increase efficiency based on customer needs and/or product requirements.

Some of the accessories are:

- Photo-eye system for registered film, allowing the use of films printed with marks to centre the design on the product

- Stable bottom device,folds the bottom of the bag to be ablde to display packages on the shelves.

- Clipping device, applies a clip or loop to the bag to give a different aesthetic appearance and to re-close the pack.

- Zipper closure,to use film reels that include the zip device to re-close the pack once opened.

- Gas flushing device, a system for modifying the atmosphere (MAP) inside the pack to extend the shelf life of the product.

- Vacuum deviceallows bags to be made, totally extracting the air inside them.

- Hanging die, “Euro slot” or “Euro hole”,allows to make a shaped hole in the bag to be able to hold or hang it.

- Special Jawsfor PE film.

- Product settler, through vibrations in the bag, allows the product to settle and the bags to be more compact.

- Package pre-cut and programmed cut, makes an incision between bags to allow manual tearing of the strings of packages.

- Stop no Film , stops the machine automatically if the film reel runs out.

- Printers/Markers, to print information such as batch number, production/expiration date or barcodes and images directly on the film in real time.

- Labellers, toapply or print labels on the finished pack or directly on the film before forming.

- Rotary table, placed at the exit of the flow-pack, receives the products already packaged to facilitate successive packaging operations.

- Automatic loaders, customised for every circumstance and need.

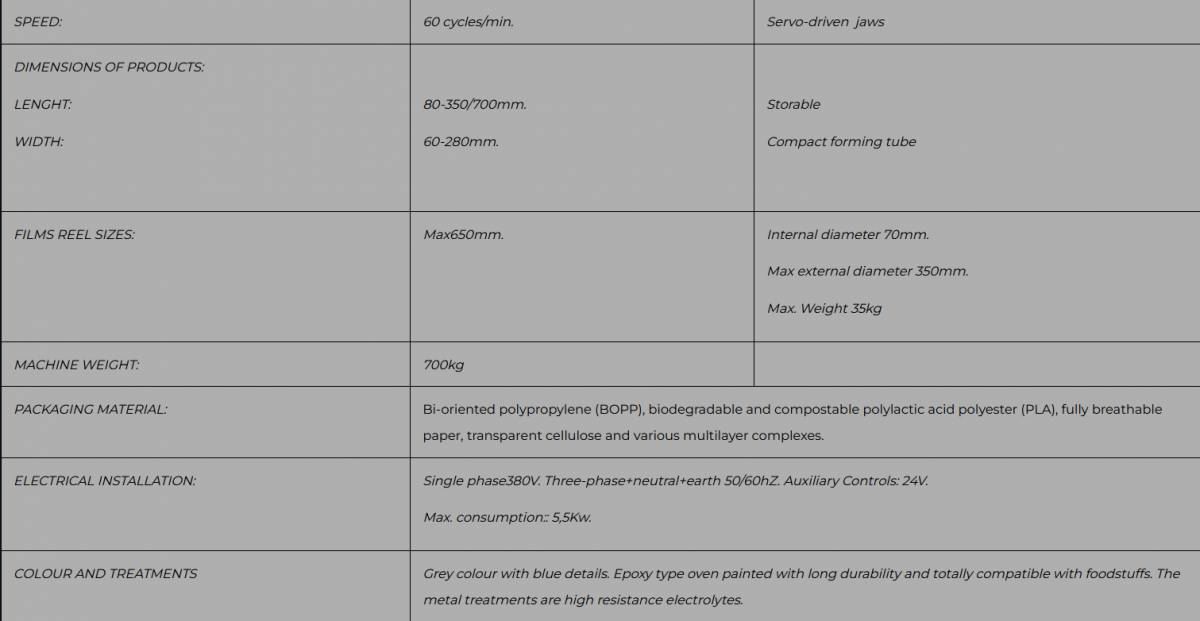

| SPEED: | 60 cycles/min. | Servo-driven jaws |

| DIMENSIONS OF PRODUCTS:

LENGHT: WIDTH:

|

80-350/700mm. 60-280mm.

|

Storable Compact forming tube

|

| FILMS REEL SIZES: | Max650mm.

|

Internal diameter 70mm.

Max external diameter 350mm. Max. Weight 35kg |

| MACHINE WEIGHT: | 700kg | |

| PACKAGING MATERIAL: | Bi-oriented polypropylene (BOPP), biodegradable and compostable polylactic acid polyester (PLA), fully breathable paper, transparent cellulose and various multilayer complexes. | |

| ELECTRICAL INSTALLATION: | Single phase380V. Three-phase+neutral+earth 50/60hZ. Auxiliary Controls: 24V.

Max. consumption:: 5,5Kw. |

|

| COLOUR AND TREATMENTS | Grey colour with blue details. Epoxy type oven painted with long durability and totally compatible with foodstuffs. The metal treatments are high resistance electrolytes. | |