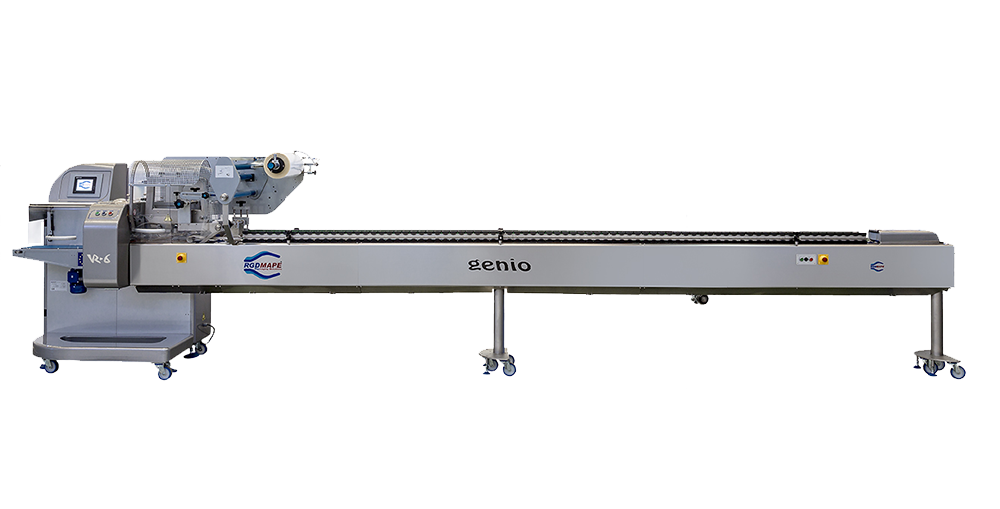

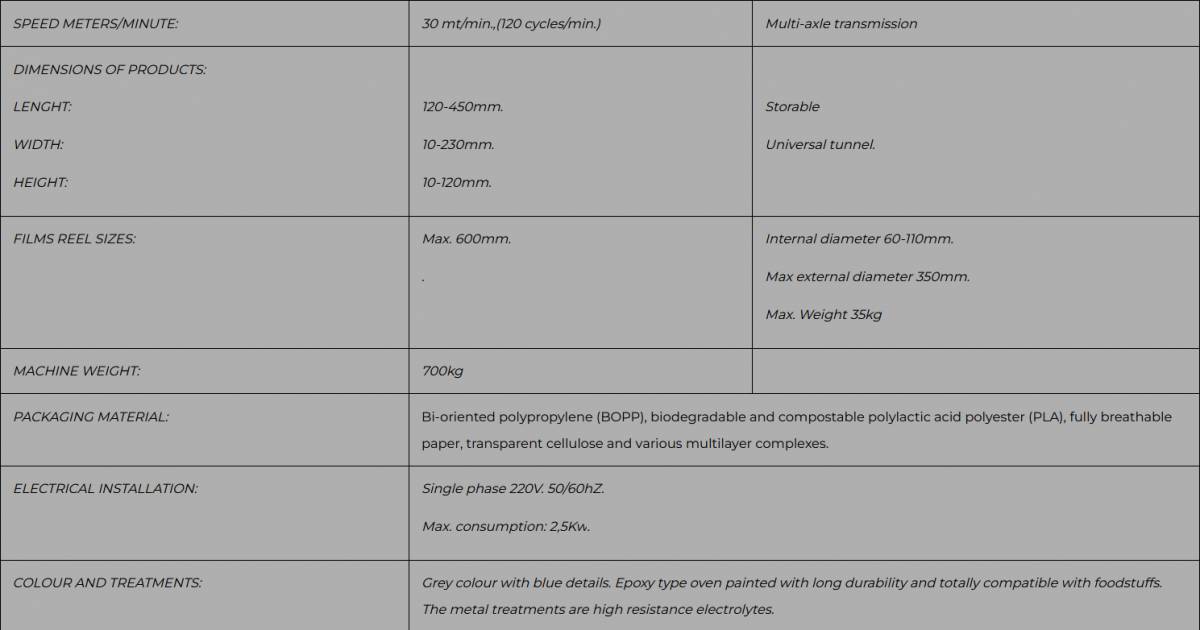

VR6 GENIO

40 years of experience designing, manufacturing and marketing packaging machines all over the world. We have the best packaging solutions on the market, thanks to the incorporation of the most advanced technologies and customisation for each product.

Our slogan “Dress your product” sums up our constant concern to offer our customers the best solution to add value to their products and present them in the most attractive way.

And all this with the greatest possible care for the environment.

ADDRESS

P. IND. PARSI

C/ PINO SILVESTRE, 46

41016 SEVILLE

SPAIN

CONTACT

+34 954 999 450

© Copyright 2023 – RGDMape

LEGAL NOTICE COOKIES POLICY