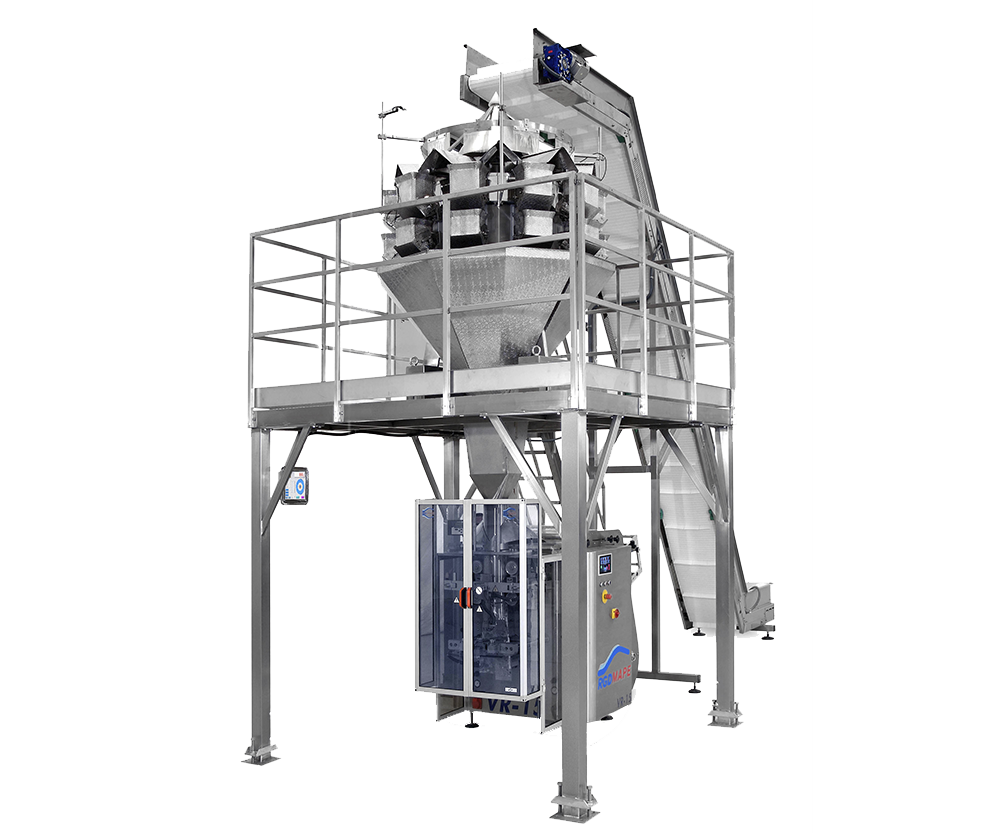

VR15 is an efficient, adaptable, and practical solution in the range of vertical packaging solutions, i.e., with infeed, bag forming, and sealing from top to bottom. This type of solution is particularly suitable for packaging bulk products, even in large quantities, which are difficult to handle with other packaging machines without proper support (trays, punnets, or other containers).

Simple in its use, the machine can thus be equipped to pack a wide range of products in the most diverse sectors. The VR15, as with RGDMAPE’s construction philosophy in general, offers the possibility of a customizable solution capable of adapting to different needs.

This flexibility is also evident in the possibility of building complete packaging lines of even very different sizes, performances, and characteristics around the machine.

Integration goes from the possible combination with an individual weighing and dosing system to high-performance multi-head weighing systems. In addition, the machine can be easily combined with the other peripherals that complete the vertical packaging lines.

No less important is the possibility of having the VR15 in an inclined version (VR15 I), an ideal solution for fragile products that require the smoothest possible descent and entry into the pack.

The machine makes it easy to work with different product formats, thus presenting itself as a suitable solution for those who need to handle various production. The ability to use it with different types of packaging materials helps make it a remarkably versatile solution that can meet the needs of those seeking packaging solutions with materials that the market requires for environmental sustainability. The high-quality materials used in the construction of the VR15 ensure its long service life, minimizing and simplifying maintenance.

The construction quality and the mechanical assemblies’ performance allow it to cope with the wear and corrosion (generated by moisture, fluids, and dirt) resulting from product packaging without any problems. The machine is manufactured with components from the most technologically advanced companies.